Control arm replacementterms of use are crucial for understanding the legal and practical aspects of this essential vehicle repair. This comprehensive guide navigates the complexities of control arm replacement, from identifying the need for repair to understanding warranty implications and safety procedures. We’ll explore the costs involved, different replacement methods, and the importance of adhering to manufacturer specifications for a safe and legally sound outcome.

This article delves into the intricacies of control arm replacement, offering a detailed look at the process, associated costs, and critical safety considerations. We examine various control arm types, outlining the unique challenges of each replacement. Furthermore, we explore the legal ramifications of improper repairs and the significance of warranties. This information is designed to empower both DIY mechanics and consumers seeking informed decisions regarding this vital automotive repair.

Get the entire information you require about metro pcs pay my bill as a guest on this page.

Understanding Control Arm Replacement

Control arm replacement is a significant automotive repair, often necessary due to wear and tear, accidents, or other damage. This process involves removing and replacing the control arms, crucial components connecting the vehicle’s suspension to the chassis. Understanding the process, costs, and safety precautions is essential for both DIY enthusiasts and those relying on professional mechanics.

Control Arm Replacement Process

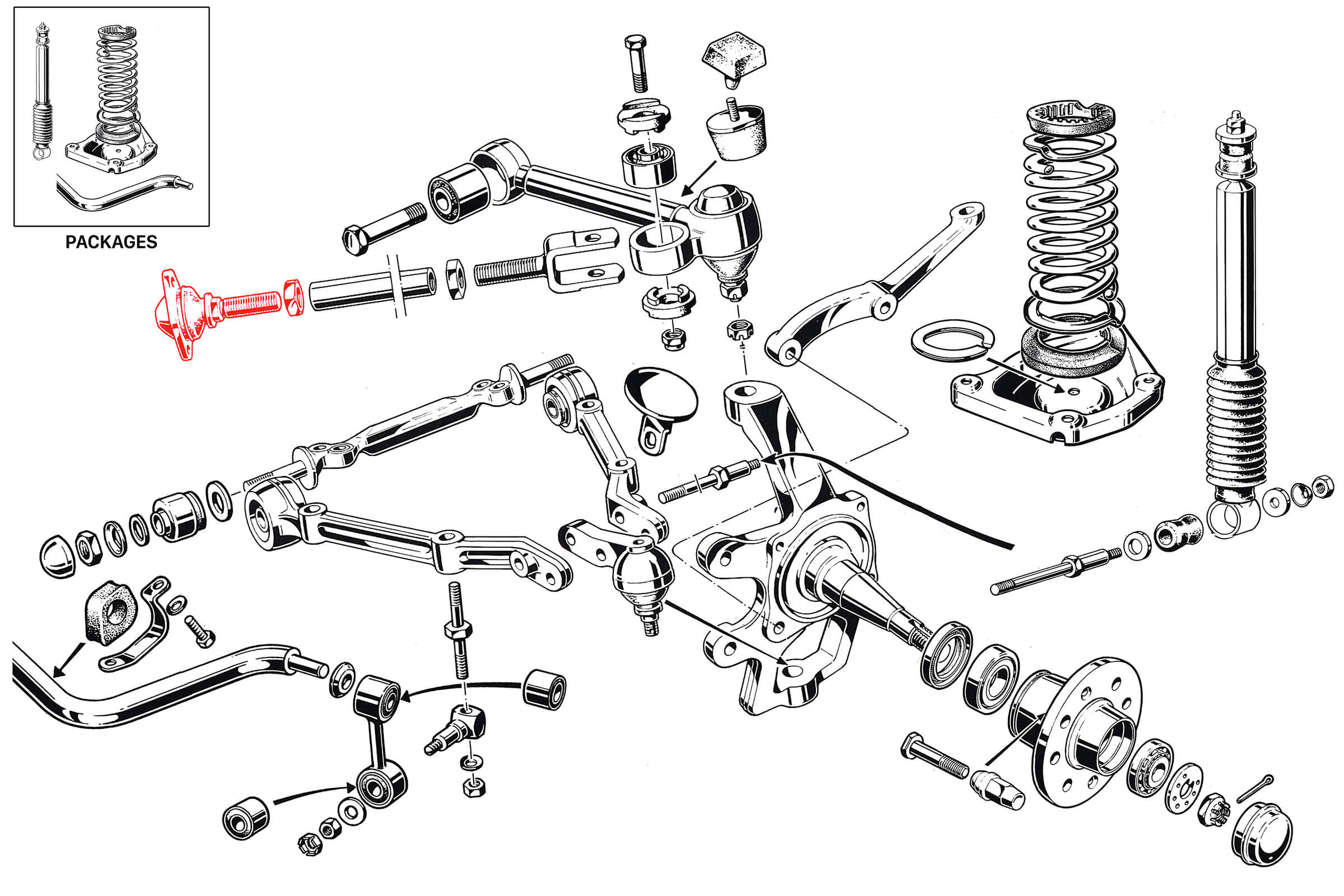

The control arm replacement process generally follows these steps: disconnecting the control arm from the steering linkage and suspension components, removing the bolts securing the control arm to the chassis and suspension, removing the old control arm, installing the new control arm, reconnecting all components, and performing a post-replacement inspection.

- Vehicle preparation: Secure the vehicle on jack stands, disconnect the battery.

- Component disconnection: Disconnect the sway bar link, brake lines, and any other connected components.

- Control arm removal: Remove the bolts attaching the control arm to the chassis and suspension.

- New control arm installation: Install the new control arm, ensuring proper alignment.

- Component reconnection: Reconnect all previously disconnected components.

- Post-replacement inspection: Inspect the work for proper alignment and functionality.

Tools and Equipment for Control Arm Replacement

Replacing a control arm requires specialized tools and equipment to ensure a safe and effective repair. Improper tools can lead to damage or injury.

- Jack and jack stands

- Wheel chocks

- Socket wrench set

- Torque wrench

- Ball joint separator

- Hammer

- Pry bar

- Alignment tool

- Safety glasses

- Gloves

Comparison of Control Arm Replacement Methods

While the basic process remains consistent, different approaches exist depending on the vehicle and the mechanic’s preference. Some might prioritize speed, while others focus on minimizing damage to surrounding components. These differences can affect both cost and efficiency.

- Pressing method: Uses a hydraulic press to remove and install ball joints, offering precision and minimizing damage.

- Hammer and pry bar method: A more hands-on approach, potentially more prone to damage if not performed carefully.

Cost and Factors Affecting Control Arm Replacement

The cost of a control arm replacement varies significantly depending on several factors. Understanding these influences helps in budgeting for the repair.

Factors Influencing Control Arm Replacement Cost

| Factor | Description | Impact on Cost | Example |

|---|---|---|---|

| Vehicle Make and Model | Different vehicles have different control arm designs and part costs. | Higher cost for luxury vehicles or those with complex suspension systems. | Replacing a control arm on a luxury SUV vs. a compact car. |

| Part Cost | The cost of the replacement control arm itself varies by manufacturer and quality. | OEM parts are generally more expensive than aftermarket parts. | OEM control arm costing $200 vs. an aftermarket part costing $100. |

| Labor Costs | Mechanic’s hourly rate and time spent on the repair significantly impact the overall cost. | Higher labor rates in certain regions or for specialized mechanics. | Mechanic charging $75/hour for 2 hours of labor. |

| Additional Repairs | Often, other components may need replacement during the process (bushings, ball joints, etc.). | Increased cost due to unforeseen repairs. | Needing to replace worn-out ball joints, adding $50-$100 per joint. |

Labor Costs in Control Arm Replacement

Labor costs constitute a significant portion of the total repair expense. These costs vary based on geographic location, mechanic experience, and shop overhead. Expect to pay anywhere from $50 to $150 or more per hour, depending on these factors. The total labor cost depends on the complexity of the repair and the time it takes to complete.

Control Arm Replacement Cost Breakdown Example

Let’s consider a hypothetical example: An aftermarket control arm costs $100, labor is $100 (2 hours at $50/hour), and additional parts (bushings) cost $50. The total cost would be $250.

Identifying the Need for Control Arm Replacement

Several signs indicate potential control arm issues. Ignoring these can lead to further damage and safety hazards.

Signs of Failing Control Arms

- Uneven tire wear

- Vehicle pulling to one side

- Wobbly or unstable handling

- Unusual noises (knocking or clunking) from the suspension

- Visible damage to the control arm itself

Consequences of Neglecting a Failing Control Arm

Driving with a failing control arm significantly compromises vehicle stability and handling, increasing the risk of accidents. Further damage to suspension components and even tire blowouts can occur. It’s crucial to address any suspected control arm problems promptly.

Control Arm Condition Checklist, Control arm replacementterms of use

Regularly inspect your vehicle’s suspension for signs of wear or damage. This simple checklist can help identify potential issues early on.

- Visually inspect the control arms for cracks, bends, or excessive rust.

- Check for excessive play or looseness in the ball joints.

- Listen for unusual noises during driving, especially over bumps or uneven surfaces.

- Observe tire wear patterns for unevenness, which may indicate alignment problems.

- Have your vehicle’s alignment checked regularly.

Types of Control Arms and Their Replacement

Vehicles have different types of control arms, each requiring a slightly different replacement procedure. Understanding these differences is key to performing the repair correctly.

Upper and Lower Control Arms

Most vehicles have both upper and lower control arms. The upper control arms typically control suspension movement in the vertical plane, while the lower control arms provide more lateral control and stability. Their replacement procedures differ slightly due to their location and connection points.

- Upper Control Arm Replacement: Often involves disconnecting various linkages and possibly removing the strut assembly.

- Lower Control Arm Replacement: Typically involves disconnecting brake lines, sway bar links, and other components connected to the lower control arm.

Challenges in Control Arm Replacement

Replacing control arms can present challenges depending on the vehicle’s design and the condition of the old parts. Access to certain bolts might be restricted, and rusted or seized components can increase the difficulty and time required for the repair.

Safety Precautions During Control Arm Replacement: Control Arm Replacementterms Of Use

Safety is paramount during any automotive repair. Failing to follow proper safety measures can lead to serious injury.

Safety Precautions Step-by-Step

- Secure the vehicle on jack stands and engage the parking brake.

- Use wheel chocks to prevent accidental movement.

- Wear safety glasses and gloves.

- Disconnect the battery’s negative terminal.

- Use appropriate tools for each task.

- Work in a well-lit and ventilated area.

- Be mindful of sharp edges and moving parts.

- Follow the vehicle’s repair manual precisely.

Illustration of Proper Safety Equipment Use

The illustration depicts a mechanic wearing safety glasses and gloves, working under a vehicle securely supported by jack stands. The mechanic uses appropriate tools, and the work area is well-lit. The vehicle’s battery is disconnected, and wheel chocks are in place. The mechanic’s clothing is appropriate for the task, free of loose or dangling items that could get caught in moving parts.

Importance of Manufacturer’s Specifications

Always adhere to the vehicle manufacturer’s specifications for torque values, alignment procedures, and other critical aspects of the repair. Using incorrect torque values can damage components or compromise safety. Refer to the vehicle’s repair manual for detailed instructions.

Post-Replacement Inspection and Maintenance

After replacing a control arm, a thorough inspection is crucial to ensure proper functionality and prevent future issues.

Post-Replacement Inspection Checklist

- Verify that all bolts are tightened to the manufacturer’s specified torque values.

- Check for any leaks or damage to surrounding components.

- Inspect the alignment of the wheels.

- Test drive the vehicle to ensure proper handling and stability.

Routine Maintenance for Extended Lifespan

Regular maintenance, including lubrication of moving parts and visual inspections for damage, extends the lifespan of the new control arm. Regular wheel alignments also help maintain proper suspension geometry and prevent premature wear.

Potential Post-Replacement Issues

Potential issues after a control arm replacement include loose bolts, alignment problems, or damage to other suspension components. Addressing these issues promptly is essential to maintain vehicle safety and performance.

Legal and Warranty Considerations

Improperly performed control arm replacements can have serious legal and warranty implications.

Legal Implications of Improper Replacements

If a poorly performed control arm replacement leads to an accident, the mechanic or individual performing the repair could face legal liability. Ensuring proper installation and adherence to safety regulations is crucial.

Warranty Applicability

Warranties on replacement control arms typically cover defects in materials or workmanship. However, warranties may be voided if the installation was not performed correctly or if the damage was caused by misuse or neglect.

Examples of Valid and Invalid Warranty Claims

A valid claim might involve a control arm failing due to a manufacturing defect shortly after installation. An invalid claim might involve a control arm failing due to damage from an accident or improper installation.

Understanding the terms of use surrounding control arm replacement is paramount for both vehicle owners and mechanics. From recognizing the signs of a failing control arm to navigating warranty claims and adhering to safety protocols, this guide provides a comprehensive overview of this critical automotive repair. By understanding the process, costs, and legal implications, individuals can make informed decisions, ensuring both vehicle safety and legal compliance.